Reacton are proud to announce that we have received Activfire listing on both our Dry Powder & Fluorine Free Foam (Reacton F3) suppression systems to AS-5062-2016. The certification comes as the latest step in our on-going global product & certification initiative, striving to have globally approved products to the highest standards and demonstrating our superior quality. The AS-5062:2016 certification is a highly recognised standard for protection of mobile and transportable equipment across multiple sectors, including: construction equipment, heavy plant & machinery and mining equipment. Achieving this certification and meeting the AS-5062 standards demonstrates yet again our commitment to delivering a safe, tested and certified product to provide industry-leading fire protection.

Vehicle fires are incredibly vicious when they break out, spreading rapidly and when combined with host of typical risks found on a vehicle they can cause devastating consequences. The combination of heat, flammable liquids, turbochargers, hot exhausts and electrical components in confined spaces across the asset, make for ideal conditions for a fire to break out.

In a fire scenario, industrial vehicles & equipment can be totally destroyed which will have a severe impact on a business’ operations, in particular when involving the construction, mining and dock and port sectors. Additionally, there is the prominent threat to life. Human life is at high risk of being compromised in any fire scenario, this is further highlighted when working in certain environments such as mines, the confined spaces and remote locations offer a real impact on fire escape and therefore life safety.

The solution lies with automatic fire suppression. In addition to this, approved fire suppression that has been tested and certified to high standards to prove that it is the most effective solution to effectively tackle a vehicle fire and prevent reignition.

What is AS-5062?

AS-5062 is the Australian Standard for fire protection for mobile and transportable equipment, the object of this standard is to formalise good practice in reducing the incidence and severity of fires in order to safeguard life, property and the environment.

It deals with the complex nature associated with mobile and transportable equipment through detailed and specific risk assessment methodologies, hazard identification, analysis and evaluations. Along with this is a series of component and fire test assessments, all designed to suit the challenging environment found within the scope of these systems.

These demanding tests are set out to test and prove the quality of the fire protection system. The testing requirements are deliberately tough to ensure that only the most worthy fire protection systems are certified for this standard. There are various elements to the testing including:

Assessment for Component Compliance:

In addition to the above the fire suppression system will be subject to a series of fire tests based on the least favourable system, when referring to Dry Powder & Foam systems the test below can be undertaken:

Just as important as the Component and Fire tests is the accurate documentation that controls the installation, ongoing support and record keeping of the systems.

These will be documents that are created and controlled in strict accordance to the requirements set out in AS 5062 , such as but not limited to the below:

The test parameters outline the stringent requirements to achieve AS-5062 certification, considering elements such as typical fire scenarios, fuels that may be present, fire risk areas and the types of agent used to suppress the fire. AS-5062 specifies the minimum requirements for the design, installation, commissioning and maintenance of vehicle fire suppression systems. It is intended to be applied to new equipment, and can also be applied to existing equipment for maintenance activities.

A consultative fire risk assessment forms part of AS-5062. Fire risk assessments should be undertaken by qualified personnel in conjunction with many stakeholders, such as equipment operators and maintainers, owners, the manufacturer’s representative, suppliers, hirers, insurers and specialist fire consultants may also be involved, as applicable. This process recognises that fire hazards and risks associated with mobile and transportable equipment are often too complex to be fully understood by one person. With the AS-5062 certification and similar existing standards and approvals in place, they ensure that maximum protection is implemented for the fire protection of mobile and transportable equipment. Such certifications set deliberately high standards to protect businesses, assets and to save lives.

How Reacton Deliver their AS 5062: 2016 vehicle fire suppression system.

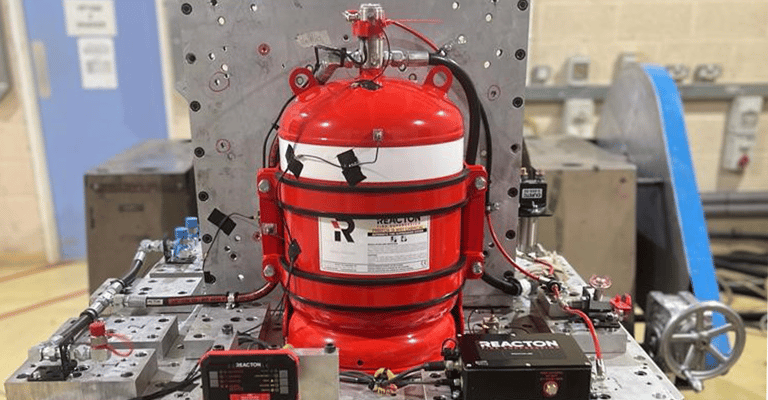

Reacton’s AS 5062: 2016 certified vehicle fire suppression system uses Dry Powder and/or our Fluorine Free Foam (Reacton F3) extinguishing mediums. The most effective solution combines both agents in what is known as “Dual Agent” which provides delivery of the powder and Reacton F3 agents separately but into the same area. The powder rapidly knocks down the fire and the Reacton F3 agent cools the super-heated surfaces, both preventing reignition. This solution has been tried, tested and approved to global standards from the leading third-party certification bodies and laboratories around the world.

The indirect automatic fire suppression system utilises two main features: its detection system and its discharge network. In the case of the Reacton Fire Suppression system, the detection system uses a pneumatic heat sensitive tube which bursts when it detects a fire or high rise in temperature, the detection tube is pressurised with nitrogen and upon bursting will activate the system. From this in its simplest form, the extinguishing agent (Dry Powder and/or Reacton F3) is released from the indirect cylinder(s) through the discharge network and is discharged through a series of strategically placed nozzles.

For more information on Reacton Fire Suppression products, please get in touch with the team by emailing info@reactonfire.com or call us on + 44 (0)800 0306526.

Reacton HQ - UK and Europe

Appledale, 1 Eastways, Witham,

CM8 3YQ, UK

Reacton Americas

23335 N 18th Dr #140, Phoenix,

AZ 85027, United States

Reacton UAE

SIDRA Tower, Office 905,

Sheikh Zayed Road, Dubai, UAE

No Comments Yet

Let us know what you think