In-Direct Release Systems

Reacton's range of Indirect fire suppression systems (ILP) offers the highest protection level for different applications with a UL2166 Listing for Indirect (ILP) Technology Clean Agent Systems. Utilising Dry Powder Agents, Wet Chemicals and Clean Agents as 3M™ Novec™ 1230 Fire Protection Fluid and FM200™ Fire Suppressant.

Novec™ 1230 Fire Protection Fluid

Manufactured by 3M™

3M™ Novec™ 1230 is a fluorinated ketone that is stored as a liquid and discharged as a gas. It is electrically non-conductive and leaves no residue after discharge. It distributes uniformly throughout the hazard zone and suppresses fire primarily by heat absorption from the flame.

FM-200™

Manufactured by Chemours™

FM-200™, sometimes referred to as HFC-227ea, is the most tested liquefiable clean agent of all time. It is an electrically non-conductive odourless and colourless gas. FM-200™ offers minimal downtime due to no clean-up post-discharge. It is stored as a liquid and introduced into the protected hazard as a clear colourless vapour. FM-200™ leaves no residue and is suitable for occupied spaces. FM-200™ has zero Ozone Depletion Potential.

In-Direct Release System

In-Direct release systems from Reacton use our heat and flame sensitive detection tubing as a primary detection method. After detection, our patented in-direct valve activates, releasing the clean agent through a network of discharge hoses and pipework. It is different from our direct-acting system, which releases the clean agent through the burst hole in the detection tubing.

What are the benefits of an In-Direct Release System?

Protect Any Cabinet

Designed to be flexible our range of electrical equipment fire suppression systems can be fitted to any cabinet or enclosure, without compromising on protection.

Easy To Install

With a modular design & world class training, Reacton ensure that it is simple for systems to be installed in cabinets and enclosures that have limited room.

3 Year Warranty

Reacton electrical equipment systems carry a robust three year warranty that's only possible because of the robust engineering and quality that goes into every product.

Easily Adaptable

Reacton systems can be integrated with any safety alarm or monitoring systems and can be adapted to any requirements of the customer.

No Electrical Power

With no reliance on electrical power or any interfacing the systems are always ready to detect and operate regardless of electricity supply condition.

BSI ISO9001:2015

Our quality management system audited by BSI ensures our products and procedures are amongst the best in the world.

Quality Components

We will never reduce our hard fought reputation for high standards. All our components are manufactured and checked with ruthless scrutiny.

Rugged Design

Tested with almost all functional components constructed from stainless steel and vibration tested to ISO.

CE & DOT

As a global business we ensure our products are compliant wherever they may be fitted. Cylinders are available in both CE & DOT specification.

In-Direct Release System

Our In-Direct systems work in the following way:

- Once the detection tube ruptures, it releases the nitrogen held within it.

- This loss in pressure causes the Reacton patented valve to operate, releasing the clean agent into the protected area. This floods the protected area extinguishing the fire.

- Additional devices such as pressure switches are activated to alert building management fire alarms and ultimately alert people that a fire has been detected.

Reacton systems are designed to meet the most robust and demanding certification standards around the world. Our automatic fire suppression systems are independent of a power source which ensures detection and suppression in any condition.

Our systems are all manufactured and designed under our BSI ISO9001:2015 quality policy and are CE & DOT Compliant. Our components undergo rigorous testing such as ISO 16750-3:2007, ISO 21207, IEC 60529:1989.

Why Clean Agents?

Reacton’s Clean Agent range consists of 3M™ Novec™ 1230 Fire Protection Fluid and FM-200™ waterless fire suppressant from Chemours™. These Clean Agents are the most trusted and tested liquefiable gases on the market, with all supply being solely through the biggest names in the industry when it comes to Clean Agents.

Reacton Clean Agent extinguishing mediums all have the following approvals:

- Underwriters Laboratories (UL)

- Underwriters Laboratories of Canada (ULC)

- Factory Mutual (FM)

- Significant New Alternatives Policy (SNAP) listed through the United States Environmental Protection Agency (U.S. EPA)

Our High-Performance Systems

Reacton uses a patented ultra-high flow fire suppression valve. The valve, made from 303 stainless steel alloy, ensures that all extinguishing agents are discharged as designed.

Our systems feature:

- Integrated Isolation Valve

- Stainless Steel alloy 303 (UNS S30300)

- Multi-Port High Flow Discharge

- Multi-Cylinder & Agent on One Detection Circuit

- Fully Vibration & Corrosion Tested

Related Applications

We manufacture safety critical automatic fire suppression systems for a complete range of assets and industries. Our solutions are backed by our protection guarantee.

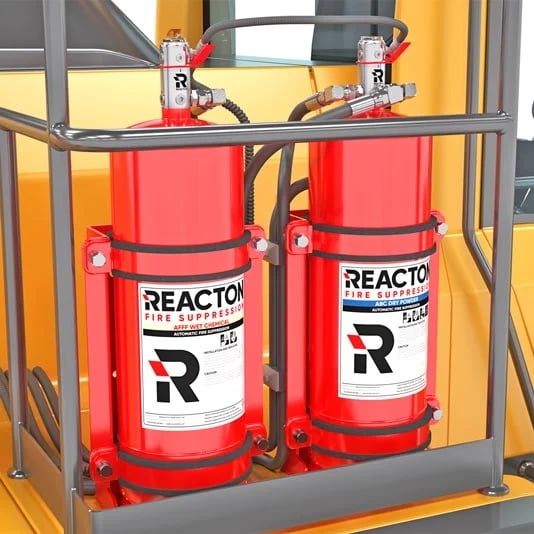

Vehicle Fire Suppression

Proven vehicle fire protection systems that perform. Our range of vehicle fire protection solutions, including a dry chemical suppression system, are designed to deal with all classes of fire including flammable liquid.

Plant Fire Suppression

Reacton's heavy equipment automatic fire suppression systems are certified to the most demanding standards such as PMark SPCR199. This standard allows a clear comparison between different types of systems. Its no surprise that all Reacton systems score A+.

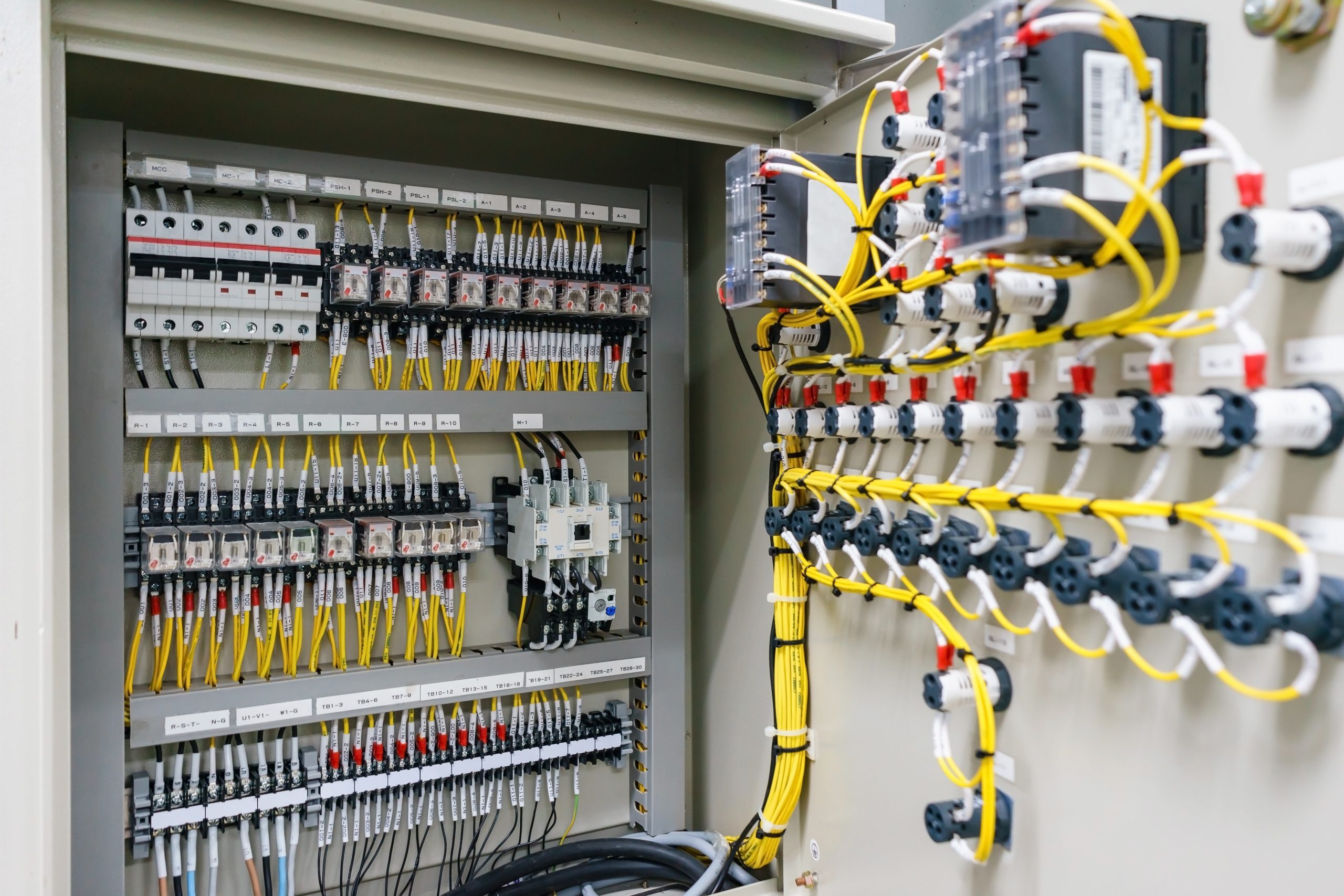

Electrical Fire Suppression

Electrical panels and enclosures are found in every industry across the world. Reacton® have a proven, cost-effective automatic fire suppression system to eliminate fires at the source.

Kitchen Fire Suppression

In residential & domestic kitchens, fires can rapidly cause severe building damage and therefore a highlighted risk for occupants.

CNC Fire Suppression

Automatic fire suppression systems to protect CNC Machines. Our CNC fire protection systems ensure that CNC machine shops are protected from the risks of fire.

Blog, News or Events

Keep up to date with our latest fire and safety news by reading our global news blog.

Why Are Dual-Agent Fire Suppression Systems Essential for Off-Road Vehicle Engines?

Why Electric Panels Need Reliable Fire Protection

.jpg)

Fire Suppression Basics for Heavy Plant Distributors

Get Protected. Find a Distributor

We manufacture safety-critical automatic fire suppression systems for a complete range of assets and industries. Our protection guarantee backs up our solutions