Clean Agent Fire Suppression Systems

Reacton Clean Agent Systems deliver lightning-fast, residue-free fire protection with world-leading approvals.

- Reliable, automatic fire protection

- Ideal for electronics, archives and machinery

- Compact & modular

- Zero clean-Up

Our certifications, your global guarantee

.png?width=53&height=61&name=SPCR%20199%20(1).png)

How it Works:

Our Pneumatic linear or electric detection runs through the hazard area and reacts at ~180 °C.

The tube either ruptures (Direct CT system) or triggers a fast-flow valve (Indirect CTX system) to release the agent.

Reacton 1230 or FM-200 gas discharges in <10 s, absorbing heat and interrupting combustion.

The non-conductive gas dissipates, leaving electronics bone-dry so operations resume immediately.

.png?width=1220&height=1208&name=Rectangle%20757%20(1).png)

Why choose Reacton

Clean Agent Systems?

- Industry-leading 5-Year warranty on Clean Agent Systems.

- Proven innovation as the first to secure UL 2166 for direct clean-agent systems.

- Made in Britain, trusted worldwide with ISO 9001 manufacturing and a global partner network.

- Faster agent discharge and deeper coverage with a patented ultra-high-flow valve.

- Single-source portfolio. Clean agent, dry powder, wet chemical & dual-agent solutions for any hazard.

- Comprehensive training & support from Reacton’s global offices for quick regional turnaround.

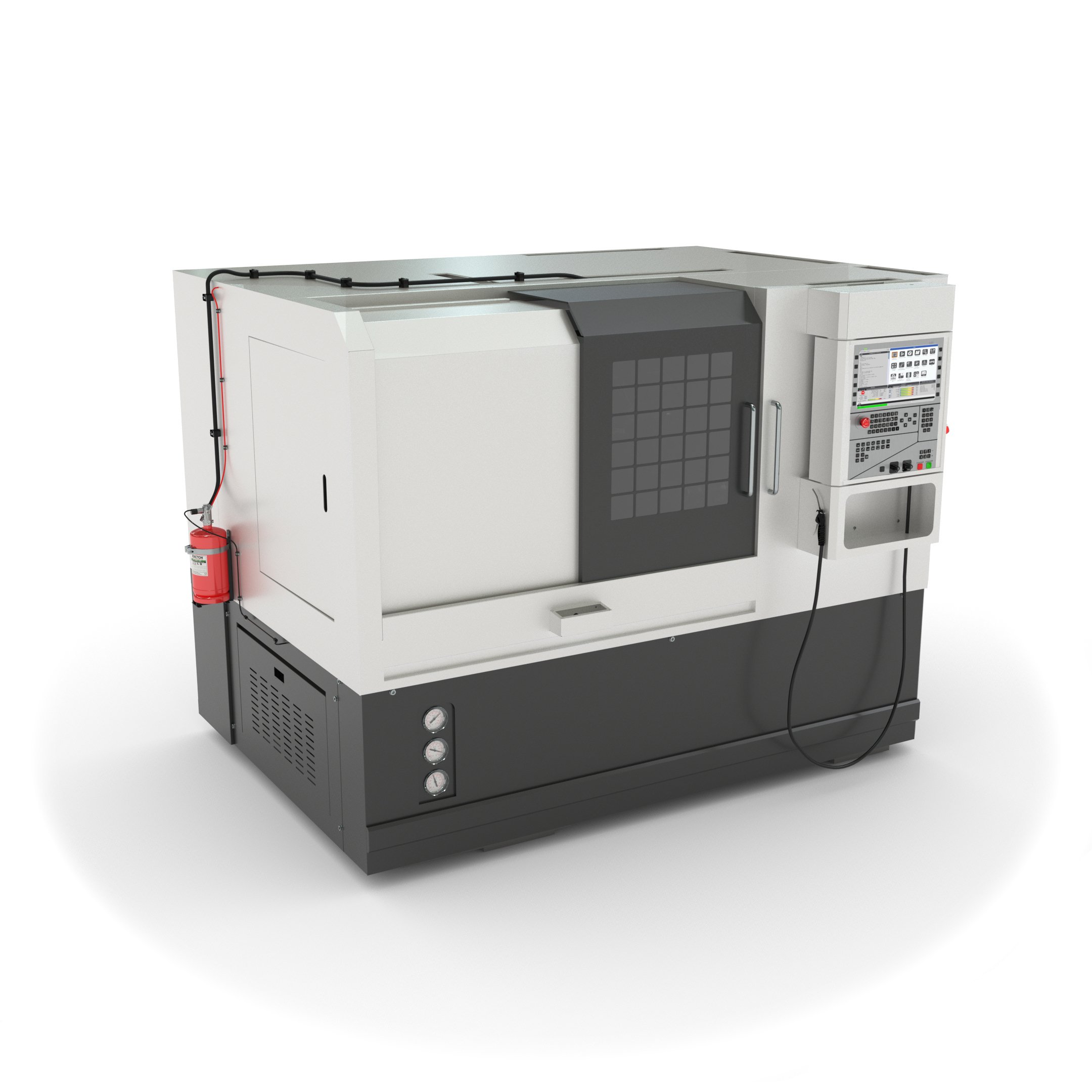

Key Benefits

No Residue, No Water Damage

Ideal for electronics, archives and precision machinery.

Fast Knock-Down (<10 s)

Stops a fire before it spreads, minimising downtime.

Safe for Occupied Spaces

Reacton 1230 (R-1230) Highest safety margin of any Clean Agent.

No Power Required

Pneumatic actuation keeps protection live during outages.

Environmentally Responsible

Zero ODP; Reacton 1230 GWP ≈ 1.

.png?width=131&height=126&name=Group-1000002706-(1).png)

Compact & Modular

Cylinder sizes from 1 kg to 18kg.

Watch our clean agent system in action

Trusted globally in mission-critical sectors

Server Rooms

& MCC Panels

Machine Enclosures

Systems (BESS)

& Brake Hubs

Laboratories

& Archives

Shelters & Broadcast Vans

.svg)

UL 2166

2 technology listings, including the Indirect CTX technology and the World-first listing for Direct CT Clean Agent technology.

%20(1).png?width=1168&height=668&name=image%20(1)%20(1).png)

LPCB LPS 1666

Clean Agent system approval.

.svg)

CE / UKCA

Cylinder conformity.

Department of Transportation (DOT)

The DOT range of Reacton cylinders will be made to the strict compliance of the DOT-4BA/4BW specifications found with the 49 CFR parts 178.61

.png?width=84&height=95&name=image%205%20(1).png)

Compliant with NFPA 2001

Standard on Clean Agent fire extinguishing systems.

ISO 9001

Manufactured under a certified quality management system to ensure consistent product performance and traceability.

Reacton’s Clean Agents are all UL/ULC Listed, FM approved and SNAP listed through the US EPA. Each being recognised and listed in standards such as ISO 14520 & NFPA 2001.

Technical Specifications

Detection

Protect What Matters Most

When every second counts, choose Reacton's Clean Agent Fire Suppression Systems, built to act faster, last longer, and restore safety with precision.

Contact us today to design a system tailored to your application.

-1%201.svg)

Reacton HQ - UK and Europe

Appledale, 1 Eastways, Witham,

CM8 3YQ, UK

Reacton Americas

23335 N 18th Dr #140, Phoenix,

AZ 85027, United States

Reacton UAE

SIDRA Tower, Office 905,

Sheikh Zayed Road, Dubai, UAE